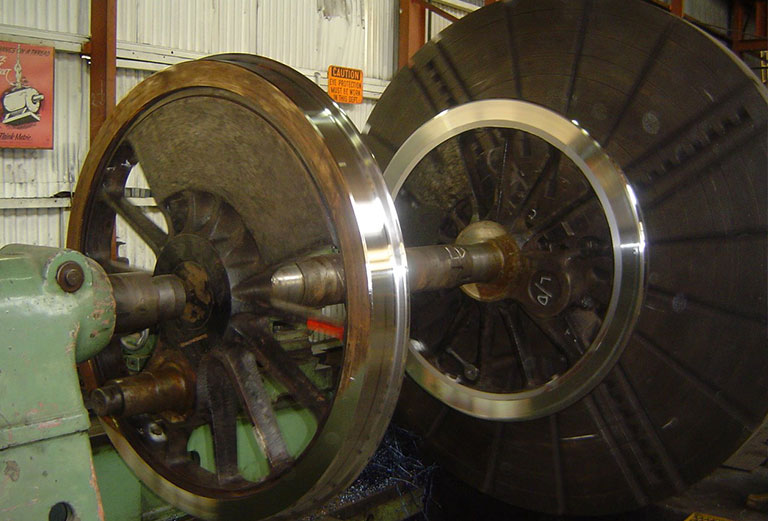

Project Scope:

Wheelset assessment and machining to client’s specifications.

Additional Info:

Heavymech was involved in the refurbishment of locomotive wheelsets for the SteamRanger Rx224 locomotive.

The work involved a full inspection of the wheelset including ultrasonic testing of the axles, machining of the bearing journals, replacement of the crank pins, and machining of the outside diameter of the wheels to restore the correct profile.

Heavymech has maintained an excellent relationship with SteamRanger. We recognise the importance of the valuable contribution made by the volunteers at SteamRanger and we are pleased to support this worthy cause.